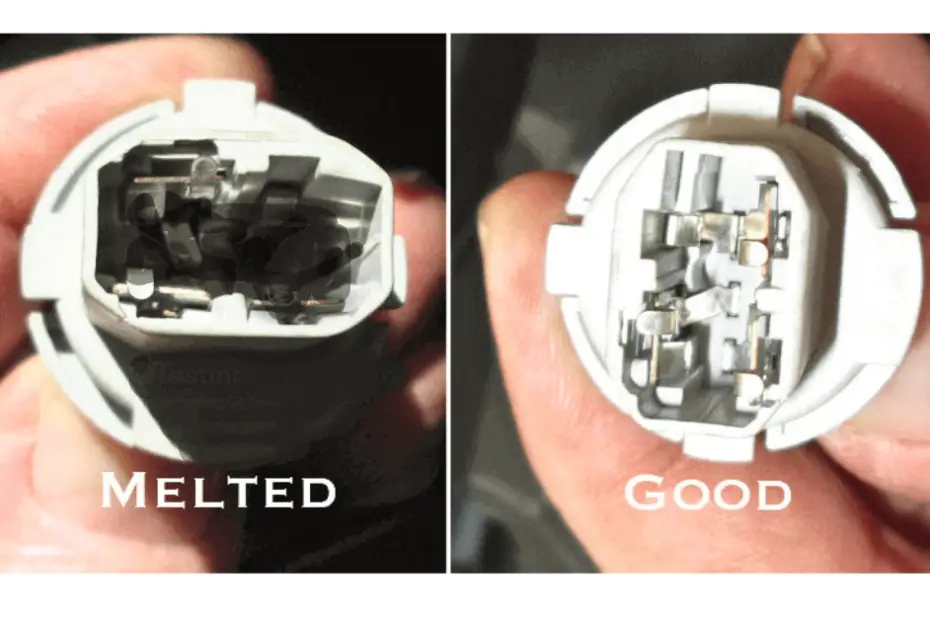

Do your headlight socket melts shortly and you get to replace it frequently? It can be due to several reasons such as corrosion, improper connections, moisture, high resistance, etc.

Once the connector melts, there’s no way to fix it; you must replace it with a new one. Instead of this frequent replacement practice, why not look at the factors which lead to this disorder?

What happens as the headlight socket melts?

Melting of the socket refers to the deformation of the plastic socket holding the headlight bulb. This socket melts and loses its shape due to exposure to high temperatures. Once the socket melts its connection with the bulb loosens resulting in;

• Flickering of the headlight

• Dimming of the headlight

• Complete failure of light functioning

• Damage to other parts of the surrounding area

Then it becomes necessary to replace the socket as soon as possible. In negligence, there’s a chance of further damage that charges you costly repairs.

Why Does My Headlight Socket Keep Melting?

If you worry, “Why does my headlight socket keep melting?”, mind that multiple causes are playing roles behind it. Figure out which of the following might be causing your headlight sockets to melt.

1. Improper Installation of Headlights:

The first thing you need to check is the proper installation of headlights. Open the casing and look whether the headlight is properly installed or not. An improprer installation refers to;

• The size of the bulb used might not fit in the socket.

• The socket used might not be of the correct dimensions to fit with the bulb.

• The socket is not properly secured or tightened in place, making loose contacts.

It’s therefore important to follow the manufacturer’s recommendations when installing headlights. Otherwise, these minor misfits may lead to major disorders.

2. Unsuitable Size of Socket:

The size of the socket can also make a headlight socket prone to melting.

For instance:

• Halogen bulbs produce bright light while consuming less energy. They use medium-sized sockets than other types. However, they generate a lot of heat due to their design. They can easily cause the socket to melt if not properly cooled with airflow.

• LED bulbs are more efficient than halogen bulbs, but consume more power. Thus they require larger sockets to handle their heat output. Whereas if installed with a regular sized socket, they may misbehave.

• Finally, HID (high-intensity discharge) bulbs produce a bright light but have high-power output. So, they are also prone to melting.

Learn more about Automotive Light Bulb Types to make a better understanding for choosing the right bulb for your headlights.

In short, all types of headlight bulbs have risks if mismatched with the size of the socket. So it’s important to use the correct size socket to avoid overheating inside.

Also, it is found in the comparison between headlights and brights that in general, high-beam headlights or brights produce slightly more heat than low-beam headlights, as they emit a brighter and more intense light.

3. Broken Wires:

Breaking of wire within a socket can disrupt the electrical current. For wiring that has been damaged, can create problems for the electrical system. It results in an increase of resistance in the circuit. Damaged wires also cause the headlight to flicker or perform poorly. Further, if these wires touch any nearby area, they may casue shorts. And this leads to an increase in heat generation within the socket.

So it’s important to regularly inspect the wiring for signs of damage. If any damage is detected, it should be repaired soon.

If you can manage to repair broken wires in the circuit by yourself, check this video guide;

4. Occurrence of Corrosion:

Corrosion is one of the most common reasons behind the melting of sockets. Corroded components in the wiring can cause electrical shorts.

Corrosion occurs due to moisture, salt, or other contaminants that settle in the wiring or at terminals. These contaminants create an electric current or arc when electricity runs through them. Thus heat builds-up causing the socket to melt.

One preventative step against corrosion is to use headlight dust caps or covers. These caps protect your headlights from dust, dirt, moisture, and other environmental factors that can damage or reduce the performance of the headlight bulbs.

Keeping the vehicle clean and dry is also necessary to reduce the risk of corrosion. It’s simple to clean the corroded socket components. For instance, check this video;

5. High-Intensity Bulbs:

The higher the wattage of the bulb, the more heat it produces. Thus, high-intensity bulbs also lead to the melting of the sockets. The socket is typically made of plastic, which has a lower melting point than metals. Prolonged exposure to high temperatures can cause the plastic to warp, or warm up.

High-wattage bulbs draw more current. This causes the wires and contacts in the socket to heat up. This results in dimming, flickering, or failure of headlight functioning.

So, it’s important to use the correct wattage bulbs specified for your vehicle. Using high-quality headlight sockets can also help to prevent melting.

6. Wiring Of Terminals:

When you Google, “Why does my headlight socket keep melting?” or “What is the most common reason for melting of headlight socket?”, 80% of results will refer to wiring.

So, it’s quite necessary to make sure that the terminals are properly wired. If not, the terminals can become too hot generating more heat. Thus uneven wiring has also been a factor behind the warming of sockets.

So, make the wire securely connected so that no bare wires touch each other or any nearby surfaces. Also, replace any old or damaged wiring with new wiring rated for higher power output. This helps reduce heat build-up in the terminals preventing the melting of the socket.

7. Age and Material of Terminals:

Another important factor to consider is the age and quality of the terminals in use. Over time, rust occurring on the connectors affects their conductivity. To avoid this, upgrading to new terminals is a viable option.

Similarly, few metal connectors are easily prone to corrosion. It is therefore recommended to use tin-plated connectors that have a high protective covering. Also, making sure to use terminals of the correct size ensures good contact. With these upgrades, your headlight sockets can remain functional for many years.

8. The Bulb Filament:

Headlight sockets can melt due to improper installation with the bulb filament. The filament is a part of the bulb that produces light when electricity passes through it. If the filament is not properly aligned with the socket, it increases resistance. This generates even more heat and can lead to socket melting.

Headlight sockets can also melt because of low-quality bulb filament. However, this is not a common occurrence. Low-quality bulb filaments may not be designed to handle excess heat. It’s therefore important to use a suitable bulb, properly installed with the socket.

9. Electrical Problems:

Moreover, electrical problems can also cause headlight socket to melt. This is because, electrical problems make wiring and contacts become hot enough. This often happens when;

- There are loose wires in the system

- Exposure to high electrical current

- When a fuse has blown and not been replaced

- Faulty wiring and connections

- Loose wires are found in the system

- Corrosion forming on the contacts inside of the socket

Bad electrical contact can also lead to the melting of the socket.

To prevent this from happening, it is important that all connections are kept dry. Also, the connections should be free from dirt and debris so that they remain conductive. Further, check all wiring regularly. Any loose wires found should be repaired immediately.

10. Moisture Penetration:

One common reason for a headlight socket to melt is moisture. Moisture can seep into the housing and cause corrosion amd wear. This results in electrical problem and corrosion buil-up inside. This condition can happen due to rainwater, snow, or even fog.

Thus proper sealing is necessary to prevent the housing from moisture. The best way to do this is by keeping the headlight socket dry. Another way for preventing from moisture is by using a sealant or waterproofing product. Check these 8 ways to remove moisture from your headlights easily at home.

If left unaddressed, this problem can cause serious damage. Therefore, it’s important to regularly inspect your vehicle’s headlights for signs of moisture damage.

Yet if the moisture has not seeped deep inside, you can still remove it at home. For instance, watch this video guide;

11. Touching The Bulbs:

Headlight socket melting due to touching the bulbs is a common occurrence. Therefore, while handling a bulb, it’s important to take safety precautions. One must always be careful not to touch the bulb with bare hands. Otherwise, the oils from the skin can cause the wires to overheat.

Also, If the glass of the bulb is cracked, it emits more heat than normal, causing the socket to melt over time.

It is important to use gloves or a clean cloth when handling the bulbs during replacement. In this way, the melting of headlight sockets due to touching the bulbs can be prevented.

12. Production of Resistance due to Current Draws:

Excessive current draw creates more resistance making the socket wires hot. This eventually leads to the melting of the plastic housing. Excessive current draws occur due to

· poor wiring harness

· Inadequate insulation

· A fuse that is too large for application

· cracked or loose connections, etc.

These factors create additional heat buildup in the socket. Hence, it’s important to check internal maintenance regularly repairing any worn-out components.

13. Weather and Temperature Fluctuations:

Another cause of melting headlight sockets is temperature fluctuations. As the temperature outside changes drastically, the plastic socket tends to expand and shrink. This repeated expansion and contraction weakens the material. Thus, moisture seeps in. Further, extreme temperatures can also damage the wiring inside the headlight socket.

To prevent this, proper insulation of headlights from external temperatures is a must. For an older car that doesn’t have insulation built-in, use a weatherproof cover for headlights. This will protect against both extreme temperatures and moisture damage.

14. Poor Quality Sockets:

Why does my headlight socket keep melting? One reason is the socket itself!

Poor-quality sockets are made out of inferior materials lacking the necessary insulation. Additionally, they may not fit as snugly in the headlight housing as they should. This allows more current to pass through generating more heat. This way, the socket gets to melt.

Over time, they also develop corrosion between the contact points inside. This can create an electrical arc that heats the socket leading it to melt.

So, it’s always best to invest in high-quality parts from a reliable source. Doing so will not only help ensure that your headlights last longer, but also keep you safe on the road by providing steady illumination at night.

15. Short Circuits:

Another reason for the melting of headlight sockets is short circuits. Short circuits can be caused by improper wiring, corrosion, or other electrical faults. These faults lead to too much current running through the headlight system. This causes the wire to overheat resulting in the melting of the socket.

First, check wires and components for damage or corrosion when inspecting lighting for a short circuit. This helps in identifying the issue. If any signs are present, then it’s likely that a short circuit is occurring somewhere in the wiring

It’s also important to check any fuses and relays in the system as these can cause shorts if damaged. Lastly, checking for any loose connections or poor insulation can help detect any shorts in the wiring as well.

See a similar case of melting treated by a car mechanic;

preventative Steps to protect your headlights

Here are some tips on how to take care of your headlight system:

- Replace the bulbs as needed

- Clean the headlights regularly

- Check the alignment of your headlights regularly

- Inspect the wiring and connections regularly

- Use a waterproof sealant around the socket to prevent moisture penetration

- Double-check your wiring installation is done correctly

- Use the right type of fuse box for your vehicle

- Protect it from rodents

Along with these precautionary measures, also make right use of headlight bulbs. Only use your headlights when necessary. Also, avoid using high beams in areas with oncoming traffic. It provides optimal visibility while driving at night or in low-light conditions.

Replacing Your Headlight Socket:

Q. Why does my headlight socket keep melting?

As discussed in the article, there are multiple reasons behind the melting of headlight sockets. The most common of those include corrosion, loose connections, poor-quality sockets, high-intensity bulbs, and moisture. You can figure out the factor responsible for the melting of your headlight socket by looking at the type of damage that occurs.

Q. How much does it cost to replace a headlight socket?

Usually, headlight socket replacements cost from around $50 to $200 or more including material and service charges. However, the cost varies depending on:

• Make and model of the vehicle

• The type of socket

• The location of the socket

• The amount of damage that occurred

However, you can also make to repair or replace your socket at home. This would require basic skills and necessary tools only. Lastly, several mechanical guides are available on the internet. Just explore and go for it.

Q. How can you replace a headlight socket by yourself?

If you have the necessary skills and tools, you can better perform replacement at home. Follow these steps:

• Make sure the engine is turned off.

• Remove the headlight assembly.

• Once you have access to the socket, disconnect it from the wiring harness.

• Reassemble the headlight housing.

• Test the headlight to ensure they are functioning properly.

Q. How long should the headlight socket last?

In general, a headlight socket can last anywhere from several years to a lifetime. But the condition with it is proper maintenance of the vehicle parts. Otherwise, natural factors like corrosion, moisture, dust, etc. may attack the system.

Q. How Often Should I Replace My Headlight Socket?

Generally, most headlight sockets should be replaced at least every few years to ensure they continue functioning properly. If the terminals seem worn out due to excessive heat or current flow, or the headlights seem dimmer, then it’s likely that you need to replace the socket as soon as possible.

Q. Why does my LED headlight flicker when the sockets are working right?

Not only the deformation of the socket is responsible for the dysfunctioning of headlights. There are several other reasons behind the flickering of headlights. If you are experiencing headlight flickering, it’s important to have it checked and repaired by a professional mechanic or auto-electrician to ensure that your vehicle is safe to drive.

Some Quality Headlight Sockets You Should Switch to:

There are a variety of quality sockets available in the market. You better switch to those to enhance the functionality of your headlight system. For example:

• ACDelco 25854672 GM Original Equipment Headlamp Socket

• Dorman 84783 Headlight Socket

• Standard Motor Products S-534 Headlamp Socket

• HELLA H84960061 4-Way Lateral Single Fuse Box, etc.

These are a few names, the headlight stores are welcoming you with numerous categories of products. Choose the right one for your headlights and stop the nightmare of recurring disorders.

However, while choosing the socket for your headlights, don’t forget to take the right measurements. Moreover, it’s better to take the mechanic’s recommendations before choosing. So that, you can get the right things to suit parts in your headlight housing.

Takeaway

Hope now you don’t question yourself “Why does my headlight socket keep melting?”. Probably you would have picked the reason causing your headlight socket to melt. Yet, the most common ones are resistance, corrosion, moistrue, improper wiring etc.

This article tried to give you an idea of what causes melting in headlight sockets and how to avoid it. With a little bit of effort on our part, we can keep our vehicles’ headlights in top condition. Have a good deal!

Explore more: